The use pressure of new pipes, especially plastic pipes, is related to many factors, such as pipe diameter, pipe wall thickness, service temperature, pipe fitting processing method, pipe fitting and pipe connection method, etc. Among them, the connection method is very important. If the connection between PVDF pipe and pipeline is not good, it will not only affect the service life of the pipeline system, but also cause the pipeline system to "run, run, drip, leak" and other phenomena. Therefore, the connection method is an important part of installation and acceptance, which must be paid more attention to.

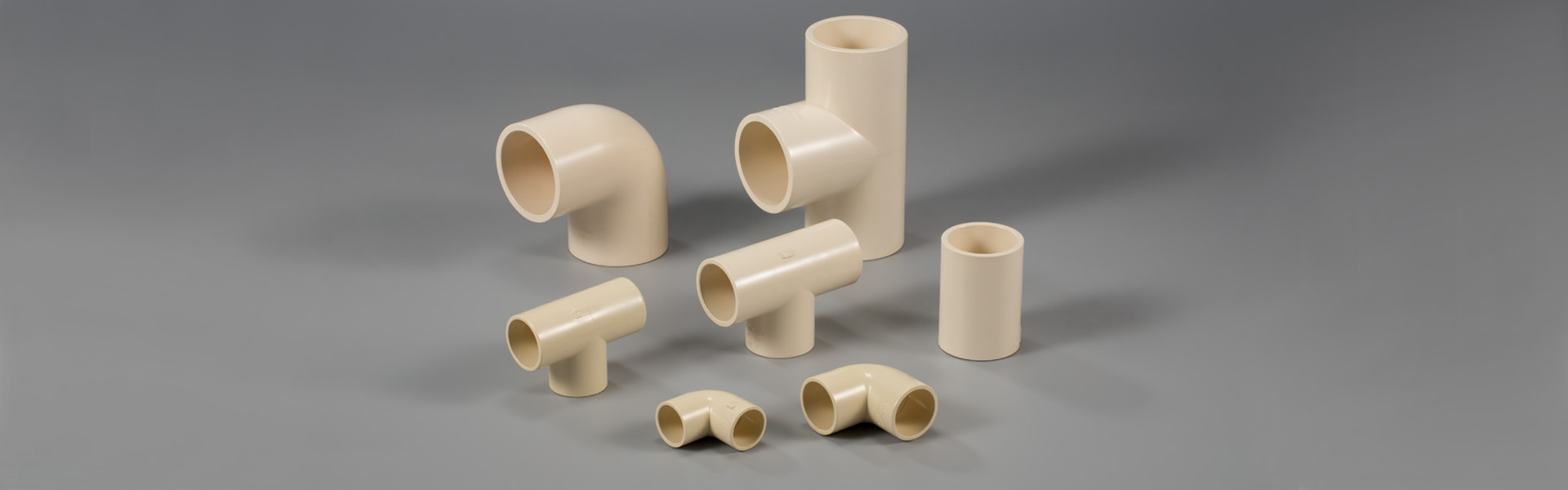

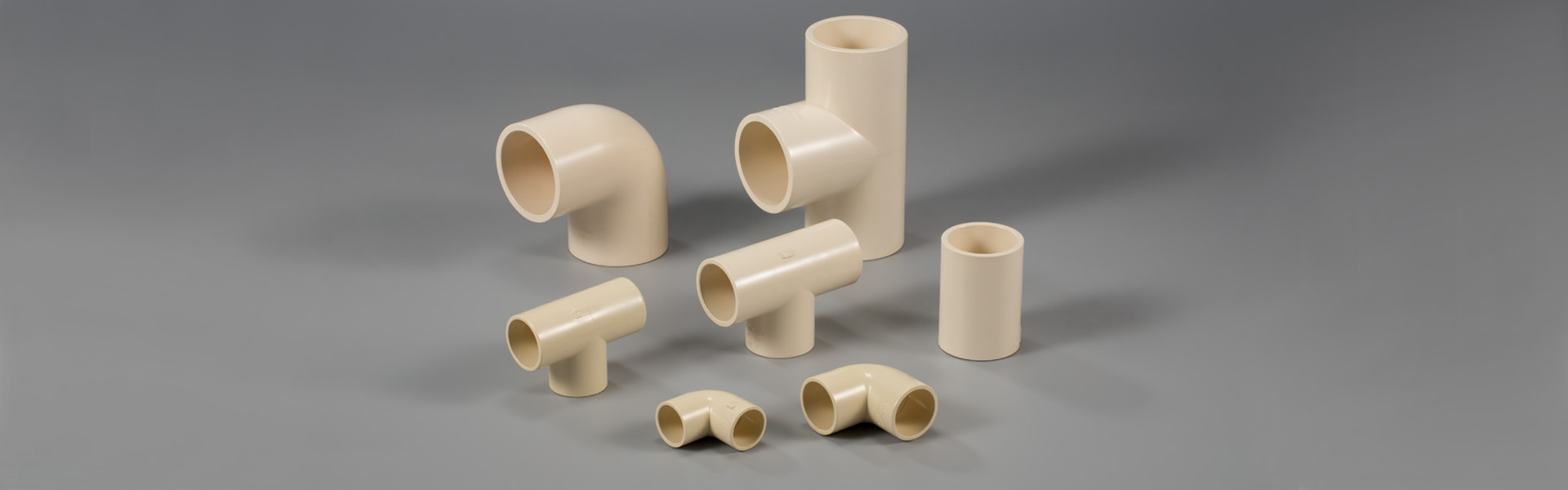

The connection method of pipes and fittings. Due to the different types of pipes and fittings, the connection methods are also different. Even if they are connected by the same method, the operation in construction is also different.

1. Hot melt connection

When the pipes and fittings made of the same thermoplastic material are connected to each other, a special hot-melt tool is used to heat the surface of the connecting part, directly hot-melt and socket it, and the cooling becomes a whole after cooling. Hot melt connection is a thermal reaction process of top heat, temperature rise, constant temperature, and temperature drop under the specified temperature conditions and in a specific model through the port of a pipe or pipe fitting, so that the melted ends are fully, uniformly and regularly Ground, completely fusion and bonding technology. Pvdf tube is not a process of chemical reaction, but a process of physical change and its result.

There are three methods for hot melt connection:

(1) Direct hot melt connection

It is to heat the connection part and directly hot-melt the connection part.

(2) Socket hot melt connection

Socket-type hot-melt connection is to heat the tube insertion end and the socket end to become soft, and then insert them quickly. After cooling, they can achieve a relatively strong combination. In order to increase the use pressure of the socket connection, one can also use the method shown, and then add a sleeve to the socket part.

There are special tools for hot melt connection, which are simple to set up and low in cost. As long as there is a 220V power supply, the connection strength is relatively high.

(3) Electrofusion connection

When the same thermoplastic pipe is connected, a special electric fusion pipe is inserted, and the electric fusion machine is energized to the electric fusion pipe. The resistance wire embedded in the electric fusion pipe is used to generate the required heat for fusion. Pipe fittings become a whole.

The PVDF tube electrofusion connection is characterized by convenient and fast connection, good joint quality, and low interference from external factors. Electric fusion connection is generally used in places where the installation location is limited and hot fusion connection cannot be implemented.