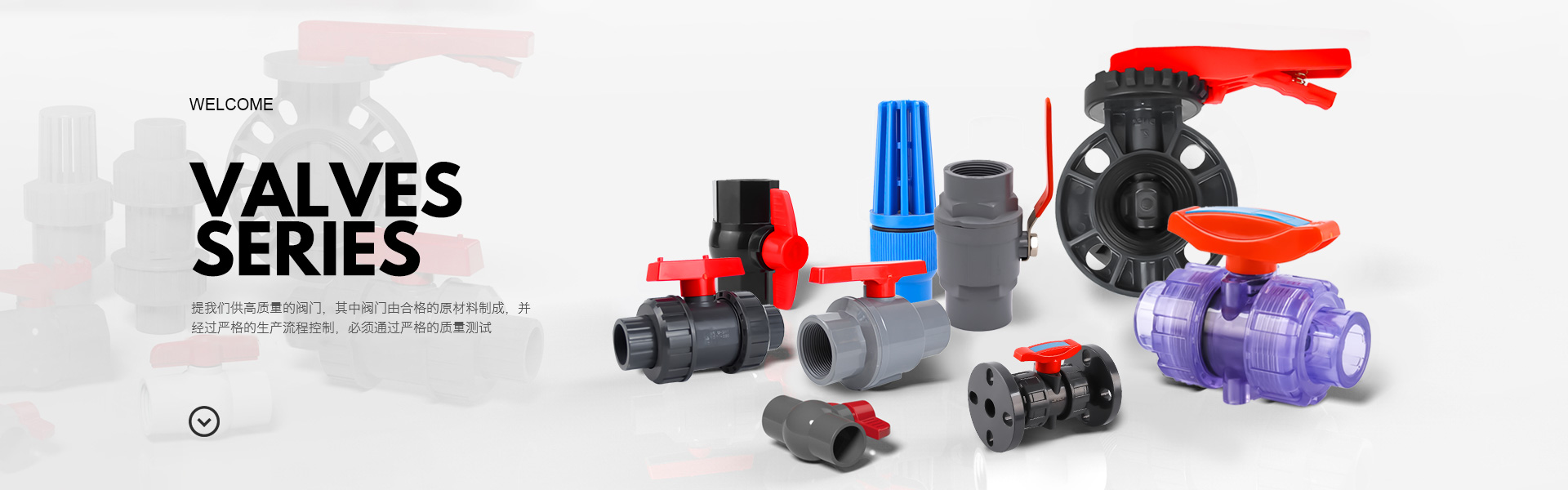

PVC valves are the third type of plastic valves used in production after polyethylene and polypropylene. Compared with the traditional materials of copper or ductile iron, the installation cost is relatively low. By adding plasticizers, they can be made softer and lighter. material. Next, let's understand the advantages of PVC plastic valve pipe and how to install and maintain PVC plastic breathing valve.

The advantages of PVC plastic valve pipe

1. Corrosion resistance: PVC plastic valves are more acid and alkali resistant than ordinary cast iron pipes and galvanized pipes, and will not rust and scale.

2. Small fluid resistance: The inner wall of the plastic valve pipe is smooth and does not adhere to scale.

3. High mechanical strength: The plastic valve has good water pressure resistance, impact resistance, and tensile strength. It can withstand 110 atmospheres for 1 hour at room temperature without breaking.

4. Hygiene and non-toxic: The unique green lead-free formula of Huanqi Plastic Valve will not damage the water quality and affect human health.

5. Convenient installation: The plastic valve has low density, light weight, easy loading, unloading and transportation, and simple and quick installation.

6. Temperature performance: The plastic valve UPVC water supply pipe is best in the temperature range of room temperature.

7. Good water tightness: 15 minutes after the interface adhesive is bonded, the bonding strength can reach 12.5/C or more.

PVC plastic breathing valve installation and maintenance:

1. For general vertical oil tanks, the fire-resisting PVC breathing valve is installed in the center of the top of the oil tank; for storage tanks that require insulation on the tank top, the fire-resisting breathing valve can be installed near the ladder platform.

2. It must be sealed when leaving the factory to avoid damage to the flange sealing surface during transportation. The fire-stop breathing valve cannot be placed horizontally or upside down. If two fire-stop breathing valves need to be installed on the top of the storage tank, the fire-stop breathing valve and the tank top The center should be installed symmetrically.

3. It is generally used for 1-3 months when installed on the storage tank. It is necessary to check whether the positive and negative pressure valve disc works flexibly.

4. The positive and negative pressure valve disc of the PVC breathing valve changes continuously according to the rise and fall of the pressure in the tank, moving up and down. When the fire-resistance breathing valve is used for three years, it is generally necessary to replace the internal valve disc, guide rod and the sealing surface of the valve seat to ensure the normal operation of the fire-resistance breathing valve and maintain the safe operation of the storage tank.

PVC plastic valves are now very popular in various industries, because their installation cost is low, and their quality and corrosion resistance are in line with construction needs. When we choose, we must choose products produced by regular manufacturers. The quality can be guaranteed at the same time There will be no worries after sale.

Taizhou Huangyan Weike Plastic Co., Ltd. is upvc van stone flanges manufacturers and pvc fitting suppliers

Visit:https://www.chinavalvefittings.com/product/valve-series/butterfly-valve/