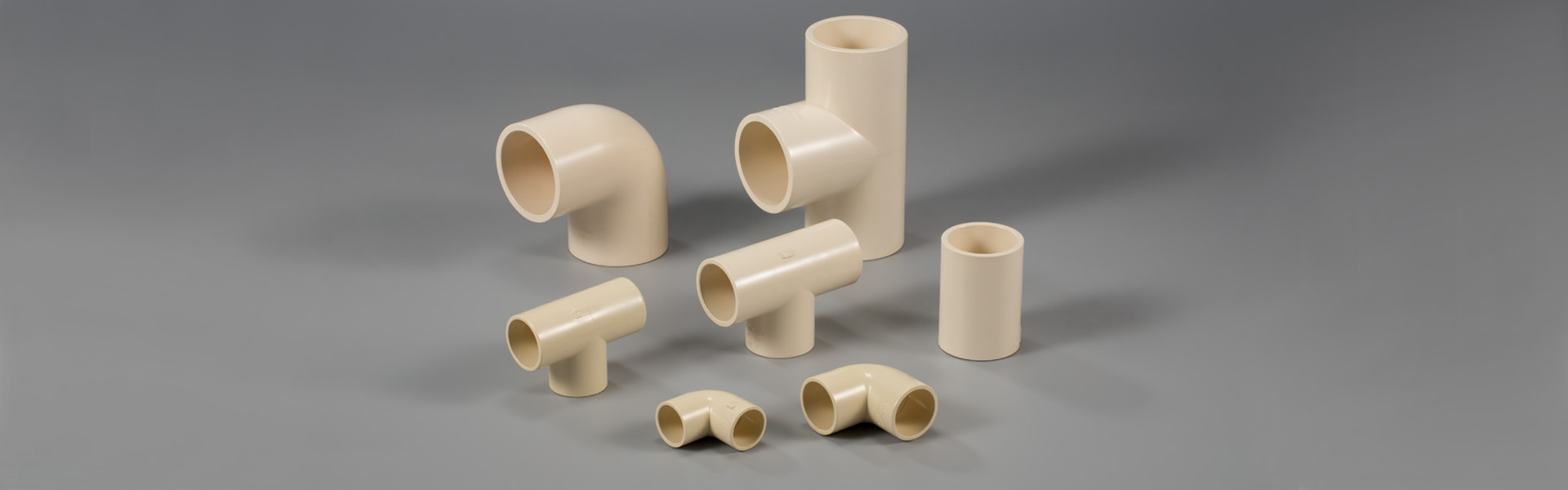

In addition to the many advantages of PVC pipes, CPVC pipes also have corrosion resistance, heat resistance, flame retardancy, etc., and their characteristics are greatly improved compared with PVC. This new type of engineering plastic is unanimously welcomed by the industry, and its excellent physical and chemical properties Received more and more attention.

CPVC pipe performance characteristics

1. Wide operating temperature range: ﹣40℃—95℃.

2. has excellent strength and toughness.

3. It has excellent chemical resistance.

4. The flame retardant performance is self-extinguishing.

5. Low thermal conductivity, about 1/200 of steel.

6. The content of heavy ions in the medium reaches the standard of ultrapure water.

7. The sanitary performance meets the requirements of national sanitary standards.

8. Light weight, equivalent to 1/5 of steel pipe and 1/6 of copper pipe.

9. The pipe wall is flat and smooth, and has small frictional resistance and adhesion when conveying fluid.

10. It is easy to install, and it can be connected by bonding, threading, etc., and the simpler is glue connection.

11. Excellent anti-aging and anti-ultraviolet properties, so that the normal service life is greatly extended than other pipeline systems.

https://www.chinavalvefittings.com/

CPVC pipeline installation and construction specification

1. The following conditions should be met before the pipeline installation project construction:

(1) The construction design drawings and other technical documents are complete and have passed the review.

(2) The construction plan and construction organization design have been approved, and the construction technology has been disclosed.

(3) Construction manpower, machinery and other auxiliary materials can ensure normal construction.

(4) Temporary facilities such as construction site water, electricity and material storage sites can meet construction requirements.

(5) The construction personnel have been trained in the pipeline installation technology of chlorinated polyvinyl chloride (CPVC) manufacturers.

2. Pipes and pipe fittings should be handled with care and neatly arranged during transportation, loading and unloading and handling. Do not subject to violent impact or sharp objects, and do not throw, drop, roll, or drag. Pay attention to low-temperature brittleness during transportation and storage at low temperatures.

3. When the temperature difference between the pipe stacking or storage site and the construction site is large, the pipes should be stacked for a certain period of time, and the installation can be done after the material temperature is close to the site conditions.

4. When installing the pipeline, place the trademark, specification and other marks on the surface of the pipeline in a position facing the observation.

5. When the pipeline is installed or the construction is interrupted, the opening of the pipeline should be sealed in time.

6. Compatible pipe fittings, adhesives and related pipe fittings should be used.

7. The paint, sealant, lubricating oil, etc. containing petroleum or solvent should be prevented during pipeline installation.